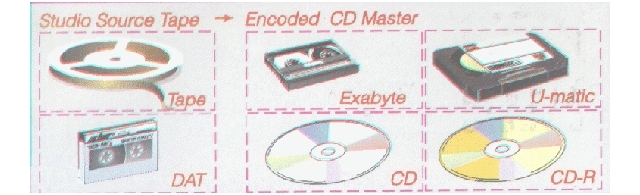

Manufacturing ProcessPremastering & Mastering of the CD-RThese processes are presently carried out overseas. The premastering process encompasses your 'disc' image being processed through a special software program and loaded onto a hard disc. The formatting is checked and error detection and correction data are added. The final 'image' is then PQ encoded and loaded onto a U-matic tape.

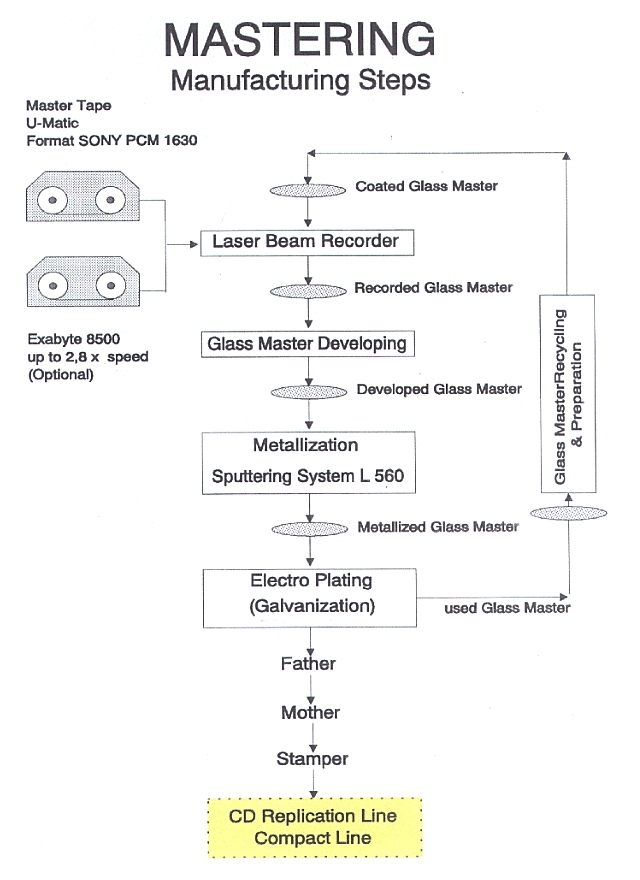

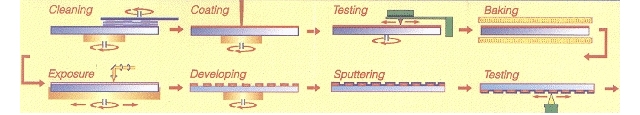

The glass blanks are coated with photoresist, spin dried, surface scanned and the thickness of the photoresist coating checked for uniformity. The glass master is then cured in a well defined computer controlled oven. Finish-coated blanks are then given a final inspection.

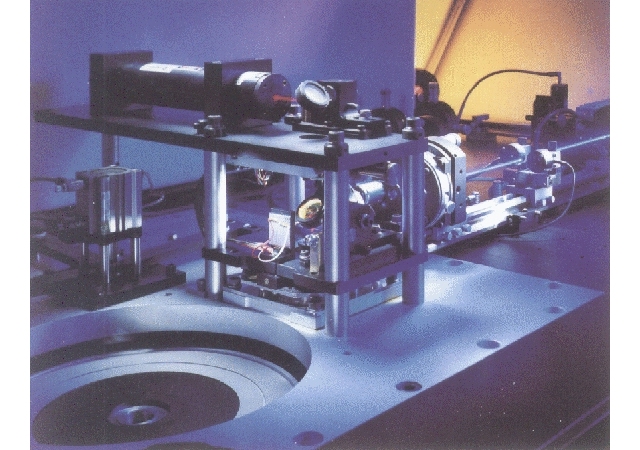

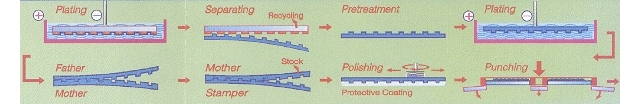

From the flow chart you will notice that a laser beam recorder is used which etches a spiral track onto the surface of the specially prepared glass master.

The glass master is metallised and an electroplating process then 'grows' the metal master on the glass, this is called the nickel father. Further electroforming will produce a positive copy of the master, the nickel Mother.

After approximately 14 days from receipt of your CD-R, CDT will receive the nickel father/mother set from the mastering company overseas. The Matricing ProcessThe nickel mother is put through an in-house electroforming process where a nickel negative is grown called a stamper. The nickel mother then becomes CDT's master and is stored in our matrix clean room.

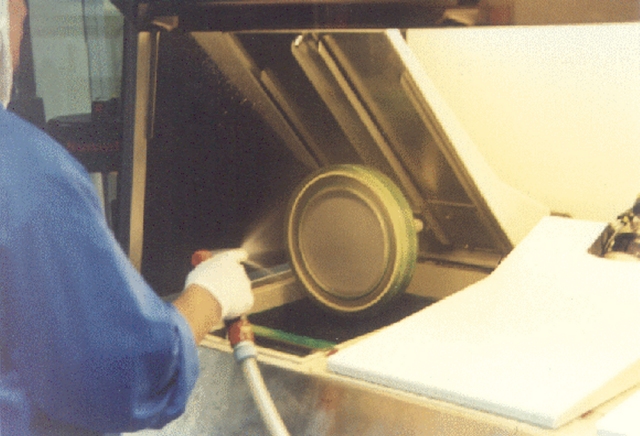

Rinsing the back of the stamper before removing from the electroforming bath

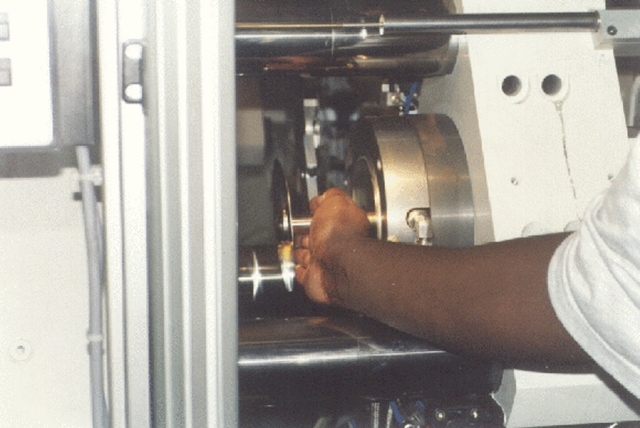

Punching the centre hole in the stamper

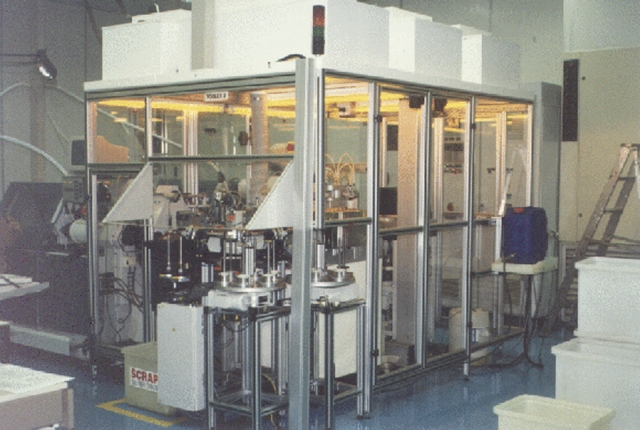

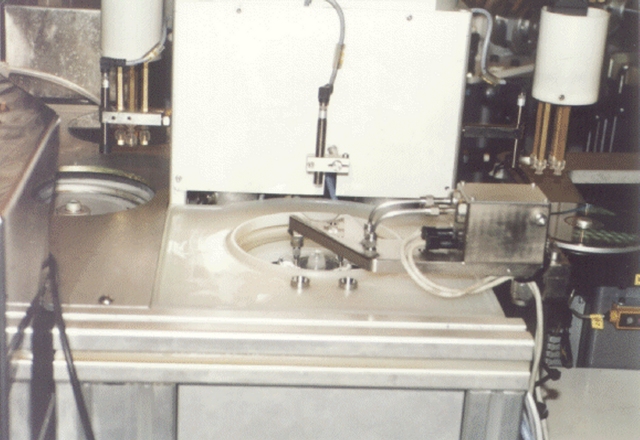

Matrix operator checking for visual defects on a stamper The Replication (Injection Moulding) ProcessCDT currently has 6 moulding machines arranged in a monoline configuration with each machine capable of producing a disc approximately every 2 - 3 seconds. The nickel stamper is clamped in the injection moulding machine. The disc is then injection moulded, producing clear polycarbonate discs with the data track on one side.

Operator clamping the stamper into the moulding machine

Toolex-Alpha Dual Liner moulding machine The robotic equipment then takes the plastic disc and places it in a metallizing unit where a reflective aluminium layer is coated over the data side of the disc. The disc is then sealed with a protective layer of lacquer.

Lacquer coating taking place Each disc is inspected by means of sophisticated test equipment on the moulding machine, to ensure that no rejects caused by scratches, material flaws, etc., pass through the system. The first discs are tested on state-of-the-art analysis equipment to verify that the discs comply with the laid down international standards. Further tests compare the manufactured disc with the original source.

Shift leader analysing discs The Silkscreen Printing ProcessCDT has 2 silkscreen printing machines, one printing up to two colours and the other printing up to 5 different colours. The printing information related to the disc is then screen printed over the lacquer surface of the moulded disc. It is essential that the printing specifications are strictly adhered to in order for CDT to produce clear, legible and quality printed discs.

Dubuit five colour silkscreen printing machine The Packaging ProcessThe discs, together with the relative inlays and booklets, are then packed by means of our automated packaging machines, into the CD jewel cases and trays. Alternative forms of packaging such as cardboard or plastic sleeves may be required, in which case the discs are carefully handpacked and shrinkwrapped for maximum protection.

Heino Ilsemann automated packaging machine Return to Computer Faire & BEXA 1995 This page last updated: 15-04-2015

|